Introducing Hangcha's XH Series High-Voltage Lithium Battery Forklifts. A leap beyond conventional design, elevating efficiency, power, reliability, and sustainability to remarkable heights.

XH Series high-voltage lithium battery medium forklift

-

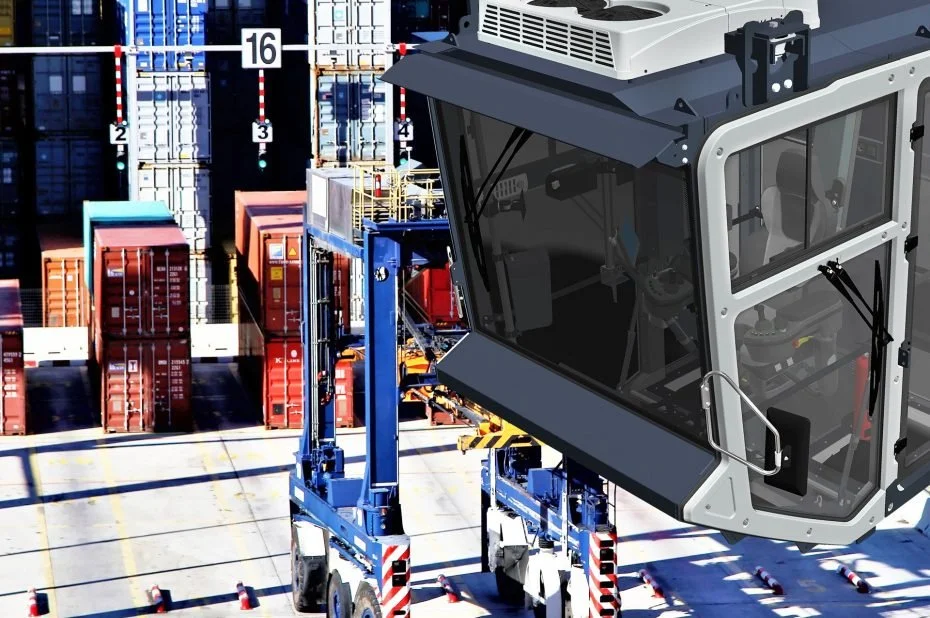

• The wide-view mast with optimized design is unlikely to obstruct the operator's line of sight. The enlarged opening size of the fork carriage enables a wider view, a large operation space, and excellent ergonomic design.

• The multifunctional color-screen instruments are designed to have graphical interfaces and display data clearly. The interfaces can be switched to be shown in Chinese and English to meet the needs of customers at home and abroad.

• The new fully-suspended cab with panoramic view enables a clearer view. Performance of the air conditioner is improved to enable uniform conditioned air blowing from the air outlet and a strong cooling effect. The waterproof, dust-proof, heatproof, soundproof, noise-reducing sealing design improves driving comfort. The molded interior parts enable a more comfortable feel. The integral frame is constituted by profiled steel pipes. The structural parts have higher strength.

• Integrated handle and pilot remote control allow flexible and accurate operation; hydraulic brake curve is optimized to achieve smooth and easy-to-control braking; suspension seat, following the floating multi-direction adjustable control platform, is comfortable to control.

-

• A vehicle central controller is provided, which has bus architecture, several built-in diagnosis and management functions and a central fault alarm function.

• An optional intelligent management system is provided to enable intelligent remote monitoring and easier equipment management and logistics management.

-

• Both the drive and operating systems are vehicle-grade permanent magnet synchronization systems. The driving speed, upslope degree and acceleration performance rival that of internal combustion vehicles, and the environmental performance is better than that of internal combustion vehicles.

• The vehicle’s 541V high-voltage platform, equipped with a heavy truck water-cooled standard box, features better heat dissipation, longer endurance mileage and more durable battery.

• This is the first time that the electric control and motor adopt water-cooled control mode, which obtains better heat dissipation, allows long-term and high-intensity work exactly like an internal combustion forklift.

• The vehicle adopts a whole machine controller to redeploy the traction integrated controller (PDU+DC/DC+MCU) and two-in-one oil pump controller to form an intelligent driving system, being light-weighted, efficient and independent

-

• The cover of the vehicle is designed to be sealed to the water resistance level of IPX4. All the motor, electronic controls and high-voltage components reach the dust and water resistance level of IP67, a high protection level adequate to withstand harsh operating environments and ensure safety and reliability.

• The electrical system is equipped with high-voltage interlocks, insulation detection, and vehicle-grade safety means. The MSD maintenance switch enables one-click power-down and safer maintenance.

• Some key structural parts have been verified highly reliable by the market for many years while being used by internal combustion forklifts.

-

• The over-turnable cab and electric tipping cylinder make tipping easier and more labor-saving.

• The wide-opened hood better facilitate repair and maintenance of electrical components.

XH Series high-voltage lithium battery heavy forklift

-

The standard configuration features a high-capacity lithium battery capable of fulfilling the requirement for extended battery life. The vehicle is equipped with efficient drive and operating systems employing energy-saving permanent magnet synchronization technology commonly found in vehicles. The utilization of a high-voltage platform results in reduced vehicle current and minimal system heat dissipation. Furthermore, the implementation of braking energy recovery significantly contributes to the extension of operational duration.

-

An adept high-torque permanent magnet synchronous motor imparts robust propulsion to the vehicle, showcasing performance metrics that are aligned with those of conventional internal combustion forklifts.

-

The vehicle is equipped with a central controller characterized by a bus architecture, encompassing various integrated diagnostic and management capabilities along with a central fault alarm function. Additionally, an optional intelligent management system is made available, facilitating intelligent remote monitoring and streamlining equipment and logistics management processes.

-

The inclusion of an overturnable cab and an electric tipping cylinder enhances the ease and efficiency of the tipping process, requiring less labor. Furthermore, the wide-opening hood and detachable cover significantly contribute to the improved accessibility for repair and maintenance of electrical components, ensuring streamlined servicing procedures.

-

The vehicle's cover is meticulously engineered to achieve a water resistance level of IPX4, ensuring effective protection against water ingress. Moreover, the electrical system is equipped with high-voltage interlocking mechanisms, insulation monitoring capabilities, and potential balancing functions, all of which collectively establish a high standard of vehicular safety.

Reliable, durable and efficient forklifts for heavy-duty material handling.

At CHS, we are committed to delivering the highest quality products in the industry to meet the unique operational needs of our clients. Reach out to us today to explore our diverse selection of machinery.

Other products