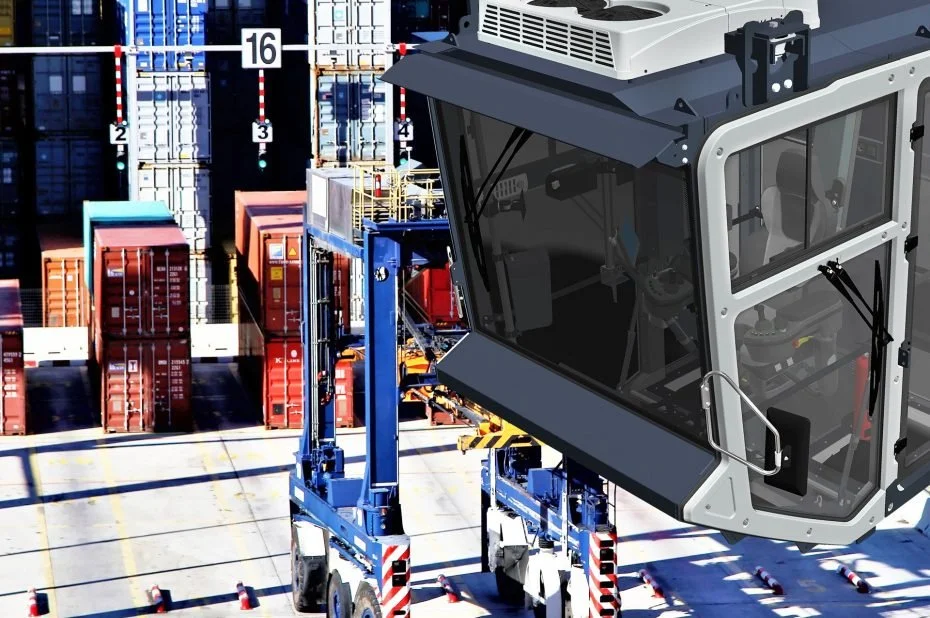

Utilizing cutting-edge technologies such as three-phase drive motors, discrete pump control, and kinetic energy recovery, the electric reach stacker demonstrates rapid operational responsiveness while maintaining minimal energy consumption. Through its adept integration of intelligent and high-efficiency functionalities, this vehicle achieves a commendable amalgamation of energy efficiency, safety, and unwavering reliability.

XH Series RS4531CH-XHJG electric reach stacker

-

The design incorporates a readily detachable hood, strategically situating all maintenance junctures in easily accessible locations. This configuration significantly streamlines the process of rectifying and upholding electrical components, thereby facilitating expedient repair and maintenance procedures.

-

The design includes an easily removable hood, strategically placing all maintenance points in accessible locations. This layout significantly simplifies the process of fixing and maintaining electrical components, making repair and upkeep faster and more efficient.

-

A robust high-torque permanent magnet synchronous motor serves as the prime propulsion source for the vehicle, delivering potent performance metrics that align with those exhibited by internal combustion forklifts. The utilization of a 618V high-voltage platform, characterized by minimal system losses, coupled with the integration of a conventional chilled water tank tailored for heavy-duty trucks, results in optimal heat dissipation capabilities. Notably, the vehicle boasts an autonomously developed VCU program, complemented by a comprehensive assemblage of PDU, MCU, BMS, and DC/DC components. This amalgamation culminates in the establishment of a dependable and efficacious drive system, characterized by its adaptable functional configuration.

-

The vehicle's casing has been meticulously engineered to ensure hermetic sealing, thereby attaining a protection rating of IPX4. The electrical infrastructure encompasses advanced features, including high-voltage interlocking, insulation safeguarding, real-time monitoring, and potential equilibrium mechanisms, collectively culminating in a safety protocol that aligns with the stringent standards expected within the vehicular domain.

-

The amalgamation incorporates American PARKER's unified hydraulic valves and variable hydraulic pump within a load-sensing hydraulic system. This synergy enables agile and accurate electric proportional control, while optimizing efficiency through swift, light-load lifting. The system further accommodates high-temperature environments up to 50 degrees Celsius through independent temperature regulation and a spacious hydraulic oil cooler.

Robust Reach Stackers:

Your Trustworthy Partners in Heavy-Duty Material Handling.

At CHS, we are committed to delivering the highest quality products in the industry to meet the unique operational needs of our clients. Reach out to us today to explore our diverse selection of machinery.

Other products